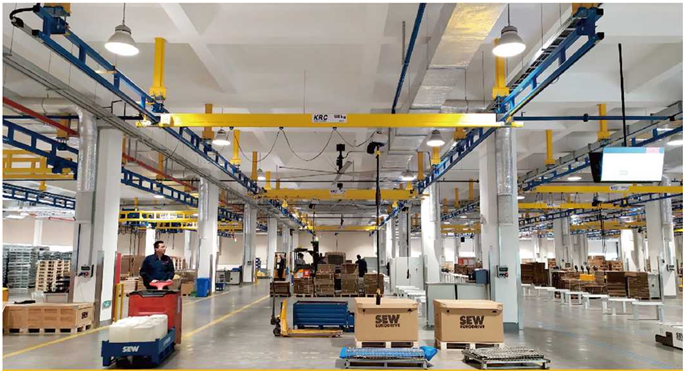

Flexibility/Rigidity Combination Crane

Flexibility/Rigidity Combination Crane that can perform the toughest overhead lifting tasks and can take on frequent overhead material handling jobs. It can be installed on ordinary reinforced concrete floors without exerting pressure on the building’s roof structure. Using a prefabricated standard modular design structure, it can be easily expanded with the expansion of the center of the work unit, and is easy to install and light to move.

HB/KBK Flexibility/Rigidity combination suspended rail crane is modular design. According to the client’s request, it could be combined freely.

Combination cranes are designed with high-strength and light-weight closed type rails. This design not only ensures the stability and safety of the crane, but also greatly improves its load-bearing capacity. By using trussed steel profile rails, it is able to realize a larger span in case of insufficient lifting points, thus reducing the number of hangers and further simplifying the installation process.

The inclusion of steel trusses allows the crane to have a span of 9 meters, which significantly reduces the obstruction of the support columns on the site. This means that the Combination Crane is able to provide a greater working range in a limited space, thereby increasing productivity. This feature has led to a wide range of applications for combination cranes in various industries, be it manufacturing, logistics or handling.

In terms of load, combination cranes are capable of handling weights of 2000 KGS . This ability makes it excellent in handling heavy loads and meets the needs of various high-intensity operations. The main beam length can be up to 10 meters, which means it can accommodate projects of all sizes, from small workshops to large production lines.

The fixed rail support spacing of up to 9 meters further enhances the flexibility of the modular crane. The modular design allows for good scalability, customization and adjustment according to actual needs. The features of light movement and precise positioning make it easy to operate and highly efficient.

It is worth mentioning that the unique design of the trolley of the combination crane not only ensures the lightness of movement, but also effectively prevents the jamming phenomenon. Rigid connection design ensures that the crane will not tilt and pull phenomenon in the working process, thus ensuring the stability and safety of operation.

In addition, the combination crane not only supports manual operation, but also can choose electric operation mode. This dual choice provides users with greater flexibility to choose according to actual needs. Simple structure, easy and quick installation is another major advantage of the combination crane. It is independently installed on the workshop floor, and the requirement for the floor strength is only concrete C30, thickness ≥ 150 mm. this low requirement makes the combination crane can be quickly and efficiently installed and used in various environments.

Overall, the combination crane has become the leader in the field of lightweight cranes with its good performance and wide adaptability. Its high-strength, light-weight design, large span and modularization make it excel in a variety of industry applications. Whether it is the logistics industry that requires frequent movement and positioning, or the manufacturing and handling industry that has high requirements for heavy cargo handling, the combination crane can meet the needs with its good performance.